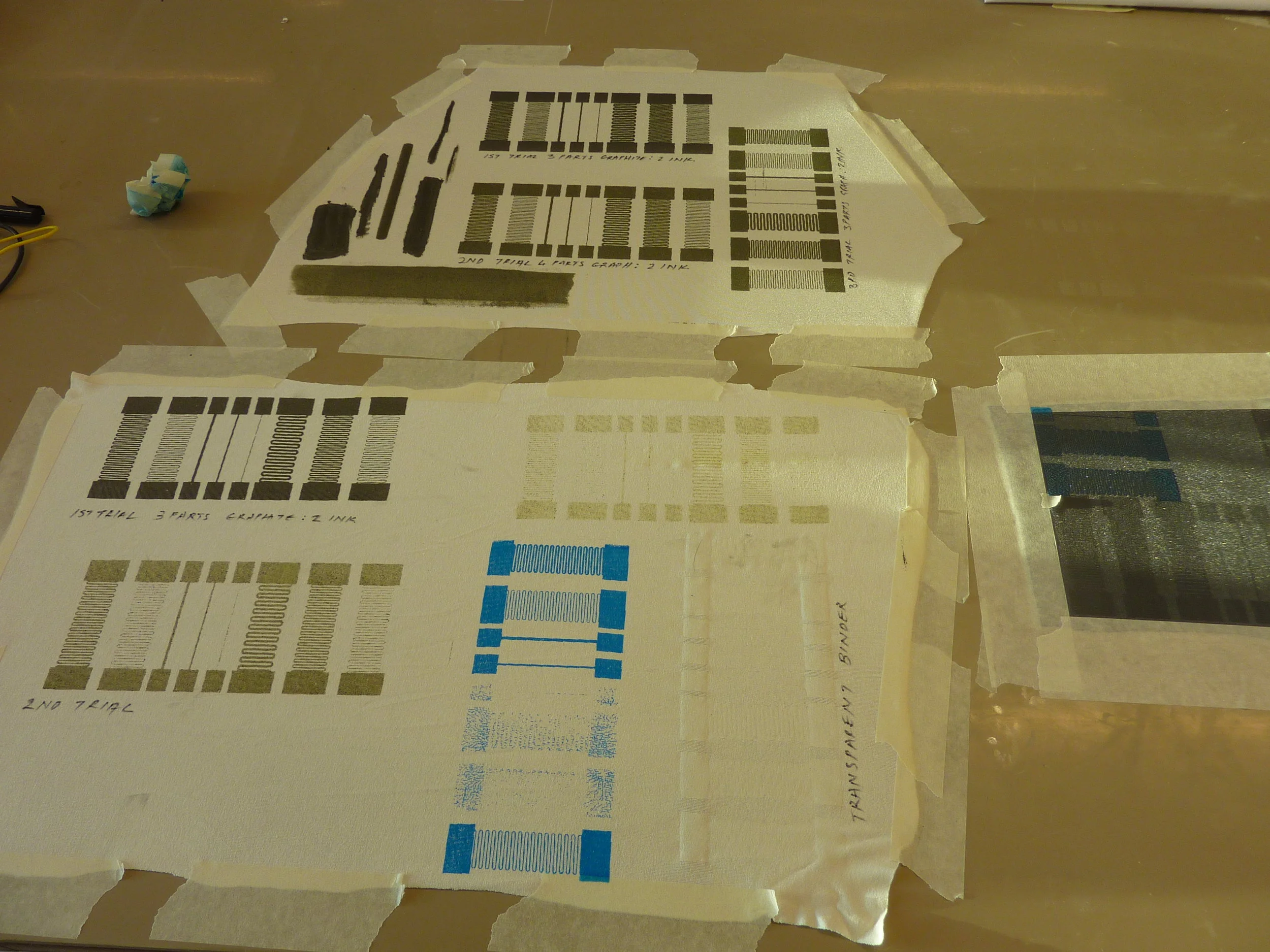

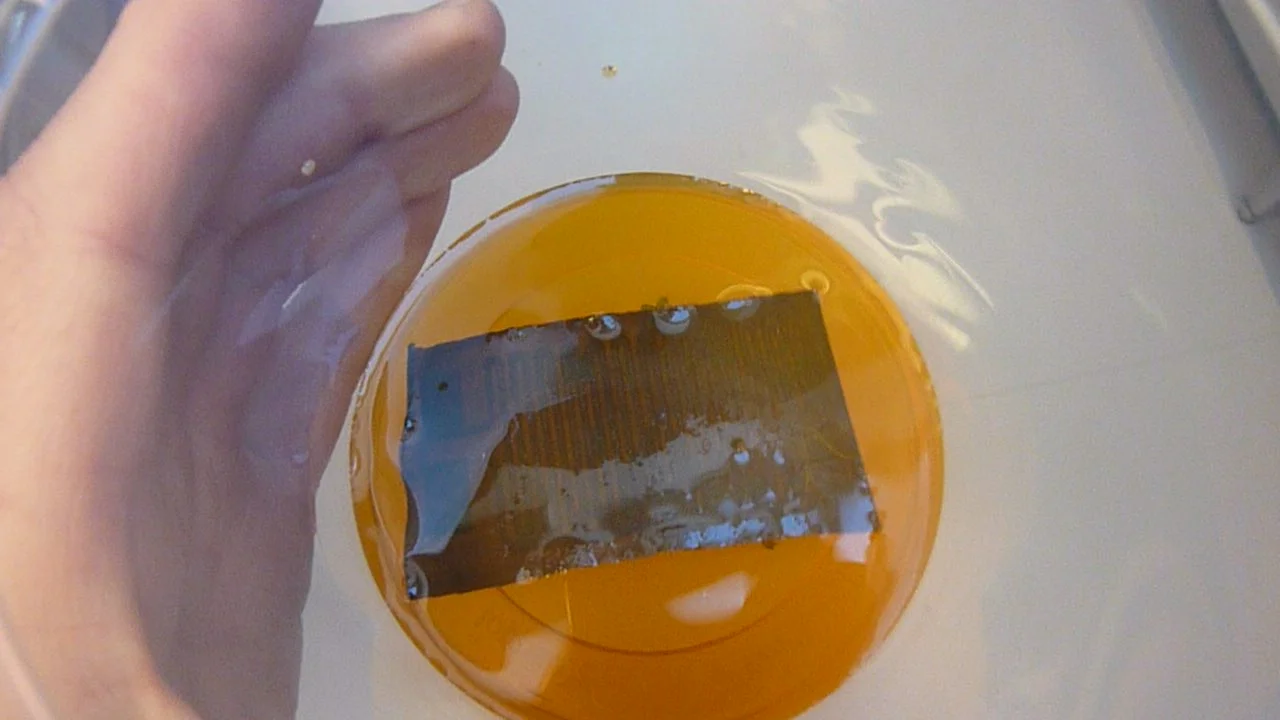

As conductive fabrics are coated in metal it is possible to use techniques normally used on metals such as electrolytic etching.

Starting with a fully metallic coated fabric it is possible to use etch away areas of the metal and create stretch sensors.

Two layers of stretch sensors where then over layed and resulted in a touch sensitive fabric surface that could also determine the force of the touch.